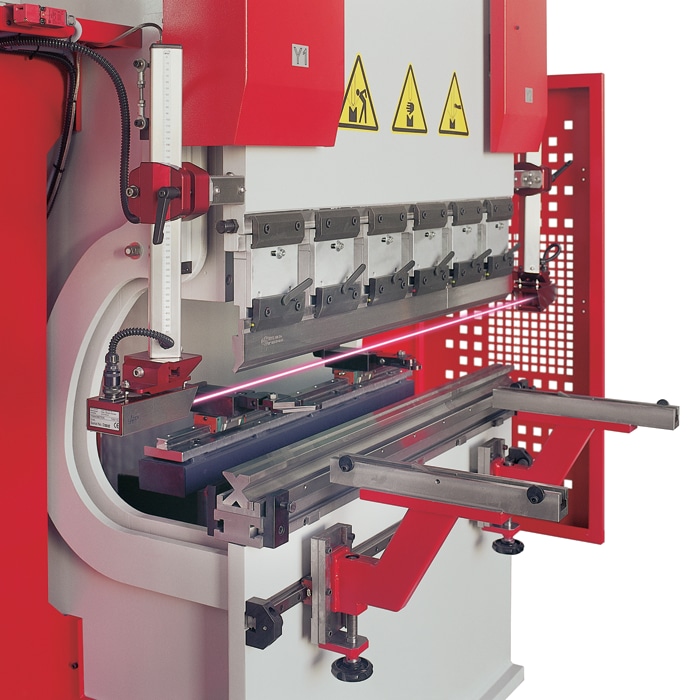

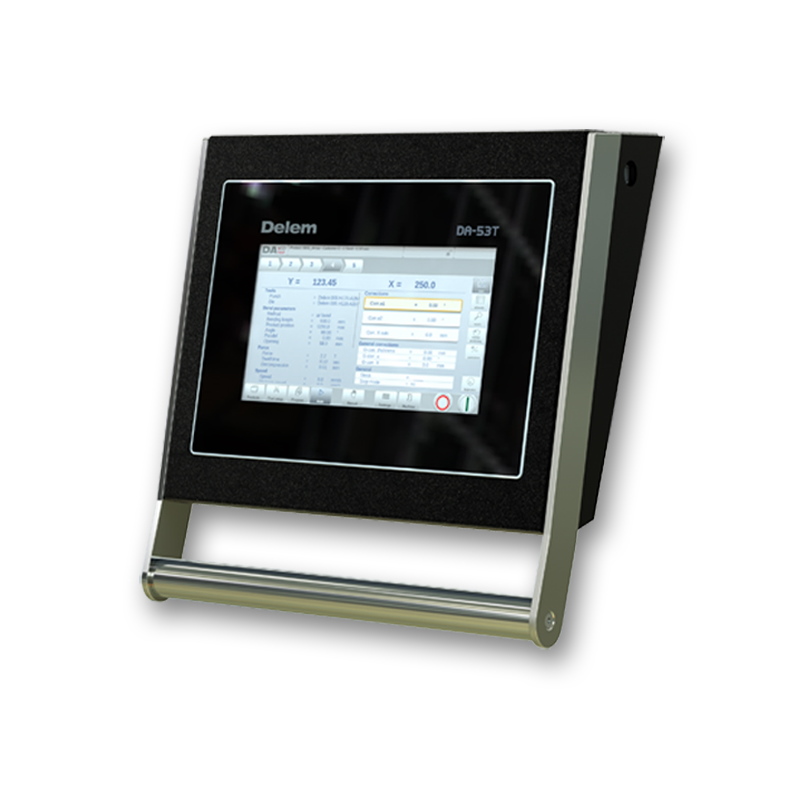

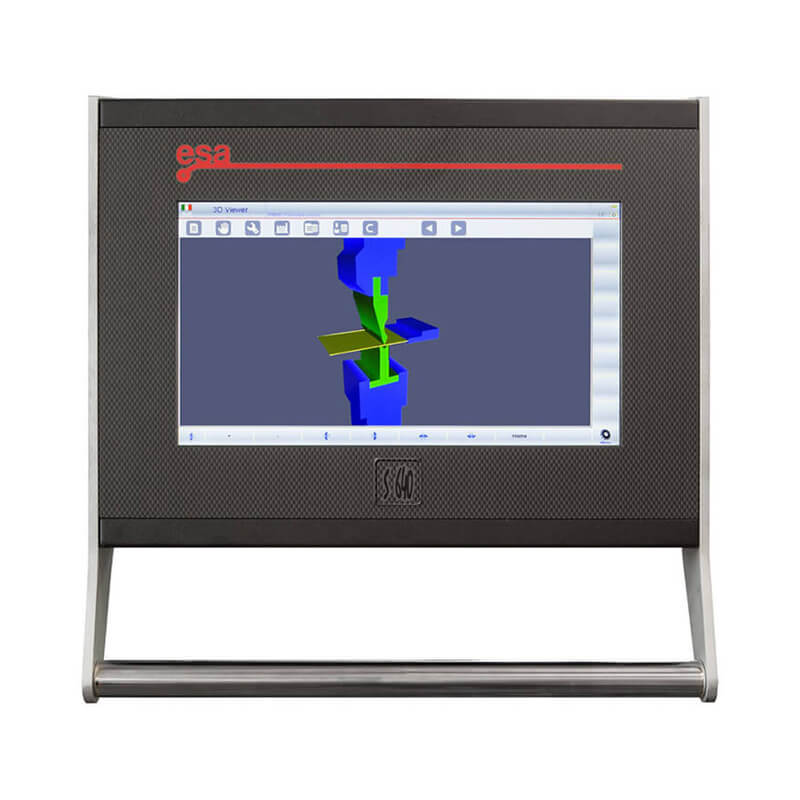

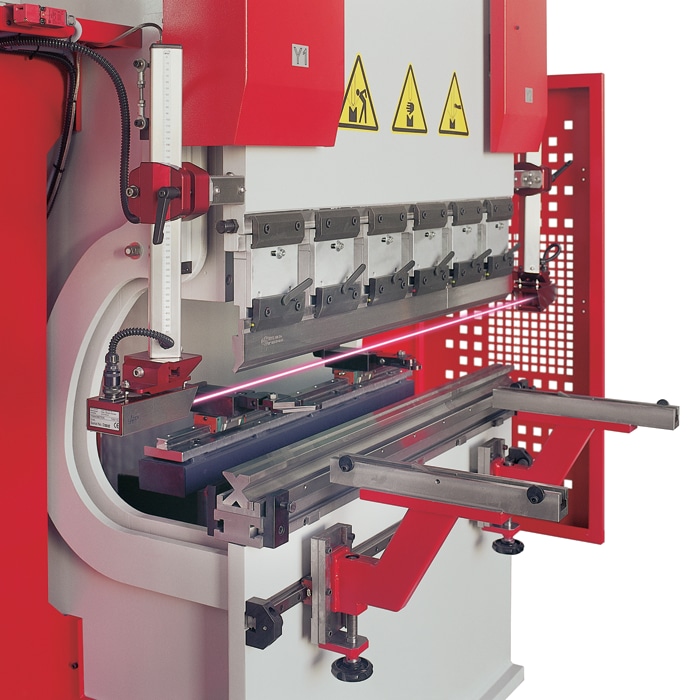

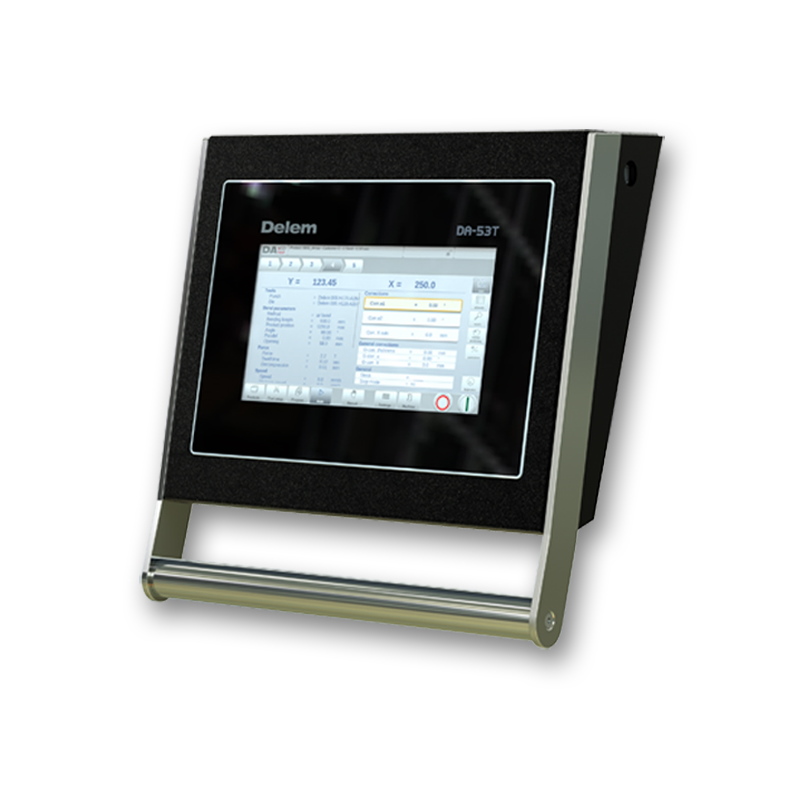

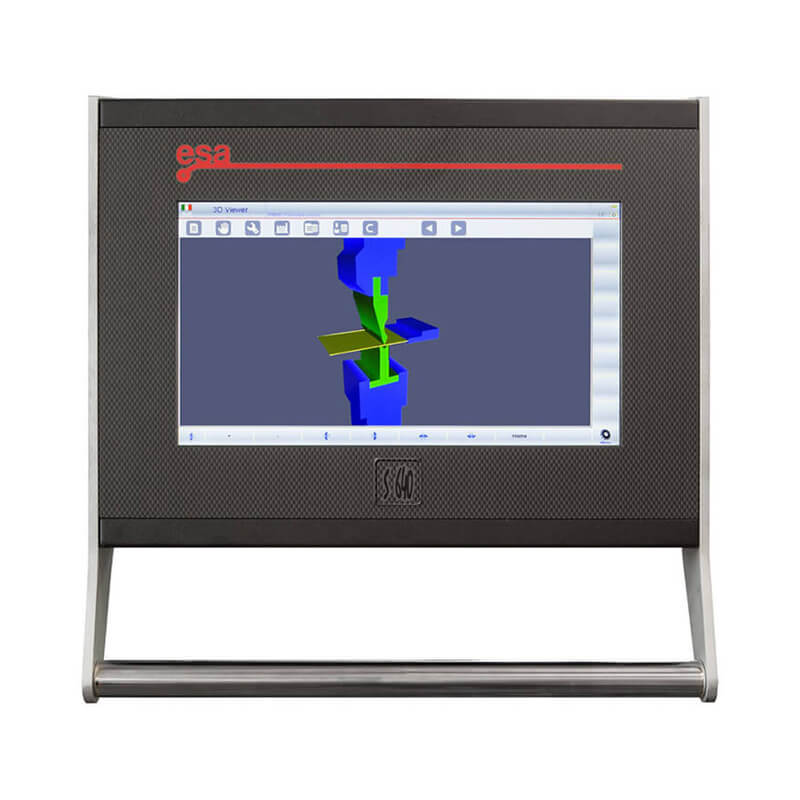

Hydraulic press brake type APHS. Easy-to-use CNC system with complete bending computations and large tool library ideal for multi-bending of complex forms, as well as for volume production which require constant repeatability. Bend accuracy and repeatability at least five-fold higher than a conventional press brake. Fully synchronised Y1-Y2 axes to ± 0.01mm via proportional valves and precision linear scales. Very fast AC servo backgauge system controlled by CNC.

HYDRAULIC PRESS BRAKE TYPE APHS

Browse our catalogues and get a deeper insight into our machines and us